Aluminum alloy explosion-proof flame arrester model:SCZ100-6

Introduction to flame arresters:Explosion proof flame arresterIt is to prevent external flames from entering storage tanks or pipelines containing gases and oils. Prevent flames from spreading within the equipment and between pipelines. Types of flame arresters

There are many types, including tank flame arresters, explosion-proof pipeline flame arresters, etc;The tank flame arrester is designed based on the principle of extinguishing flames due to heat loss when they pass through narrow pores of a thermal conductor

manufacture. The fire-resistant layer structure of tank flame arresters includes gravel type and wire mesh typeOr corrugated type. And explosion-proof flame arresters are used to prevent gases and liquidsThe spread of flames and prevention of tempering caused by backfire

equipment The flame retardant layer inside the flame arrester is made of stainless steel strip or copper nickel alloy material pressed into a corrugated shape, and the size of the ripples is determined by the properties of the gas and the speed of flame prevention.Explosion proof flame arresters are usually installed

During transportation or dischargeOn gas storage tanks and pipelines. Like torches, heating combustion systems, petroleum gasRecycling system or other gas systems. Due to the particularity of its application environment, the design of flame arresters

The requirements are also quite strict.

|

Product Name: |

Aluminum alloy explosion-proof flame arrester |

|

Scope of application: |

Diesel, gasoline, coal gas, natural gas |

|

Operating Temperature |

-30-+60℃ |

|

Valve body material: |

aluminum alloy |

|

Flame retardant core material: |

Stainless steel corrugated plate |

|

Specifications: |

DN50-200 |

|

brand |

Shanghai Nanshi |

aluminum alloyExplosion proof flame arresterstructural designThe product consists of two parts: the core and the shell. The core is made up of two layers of ultra-thin stainless steel strips, one pressed into a wavy N shape and the other

flat steelThe belt is tightly wrapped around the center of the circle. Thus constituting nothingnumberThe end face is a small triangular straight channel, and there is a cross shaped support structure inside the core (or on the surface)

Press on the Y-shapeTo enhance the reliability of the core components and prevent the explosive pressure generated by the ignited medium from dissipating. Medium narrows from a trianglePassing through the path, the flame arrester also comes through it

The principle of preventing the spread of flames in pipelines is the "wall effect"'The collision between the flame and the vessel wall converts energy, reducing the temperature. Design the height resistance of triangular holes based on this principle

The flame stopping passageBy adding sufficient channel length to absorb the heat of the flame, it can be extinguished in the core, avoiding the possibility of gas reigniting at the other end of the core.

The main points include the following: the material requirements for the shell itself are relatively strict, generally using media such as aluminum alloy, stainless steel, cast iron, etc., and the size must be executed according to the prescribed standards; During the manufacturing process

The castings used for its shell must not have any damage or cracksProblems such as wrinkles and sand holes can affect castingsThe effectiveness of use;During the shell manufacturing process, a water pressure test should be conducted according to regulations

Verified and can only be used after passing the inspection;The flame arrester with corrugated structure will be processed and manufactured using steel strips according to regulations. Such steel stripsIt should be bright and free from oil stains and rustSpot stains;On the fire-resistant layer

The pore size should be completely consistent and evenly distributed, so it should be kept unobstructed;The fire-resistant layer installed inside the shell cannot shake, so its contact surface needs to be tightly combined before completing the assemblyAfterwards, I

We also need to conduct flame retardant tests according to regulations.

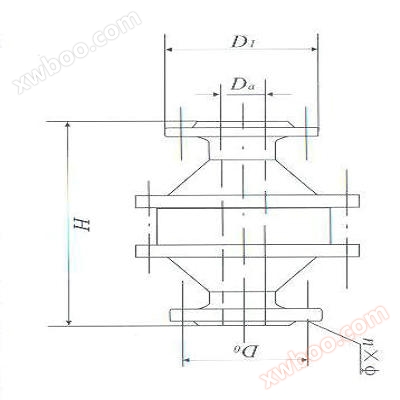

aluminum alloyExplosion proof flame arresterSize and Structure Diagram:

|

Specifications(DN) |

D1 |

Do |

H |

N |

aperture |

|

50 |

140 |

110 |

175 |

4 |

Φ14 |

|

80 |

185 |

150 |

215 |

4 |

Φ14 |

|

100 |

205 |

170 |

220 |

4 |

Φ18 |

|

150 |

260 |

225 |

240 |

8 |

Φ18 |

|

200 |

315 |

280 |

260 |

8 |

Φ18 |

aluminum alloyExplosion proof flame arresterexecution standard:GB13347-92Fire resistance performance and test methods of flame arresters for petroleum gas pipelinesSH/T3413-99Petrochemical Petroleum Gas PipelineRoad obstruction fire

Selection, Inspection, and Acceptance of InstrumentsHG/T20570.19-95The setting of flame arresters.flame arresterProduction and inspectionInspection and acceptance criteria:SY/T0512-1996Fire arresters for oil storage tanks

Test basis:GB5908-86Performance and experimental methods of flame arresters for oil storage tanks.

aluminum alloyExplosion proof flame arresterInstallation and MaintenanceThe connection between the flame arrester and the pipeline can be installed horizontally or vertically. Regular inspections should be conducted, and if blockages are found, high-pressure steam, compressed air, or other materials should be used

Clean the machine solvent, if mechanical damage or corrosion by the medium is found on the core componentsAfterwards, it shouldReplace immediately.

Shanghai Nanshi is a professionalManufacturer of flame arrestersThe products produced by the company include breathing valves, flame arresters, fire-resistant breathable caps, fire-resistant vacuum pressure caps, aluminum alloy ball valves, and aluminum

Alloy single flange ball valve, oil discharge port, double door bottom valve, oil measuring hole and other systemsList supporting attachments.

Welcome to visit our website【http://www.shhxfcj.com】,If you have any questions.You can call us,weWe will do our best to provide you with high-quality service.

Telephone:.