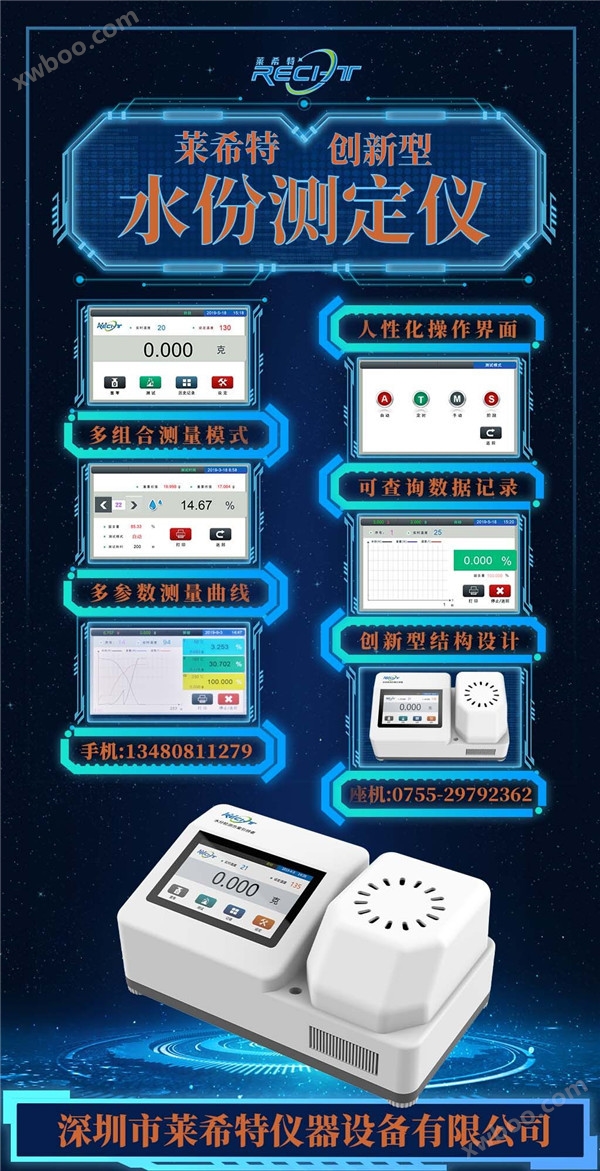

Coal moisture content tester

Application field of coal moisture content analyzer: The Lechte LXT-160 coal moisture content analyzer can be widely used in all industries that requi

Product details

The Lechte LXT-160 coal moisture content analyzer can be widely used in all industries that require rapid determination of moisture content, meeting the moisture detection requirements of every link in enterprise production and processing. The product is widely used for rapid detection of moisture content in raw materials, powders, particles, semi-finished products, finished products and other materials. The coal moisture content analyzer can accurately provide moisture detection solutions for samples such as mineral powder, slag, coal, coal powder, inorganic powder, fly ash, soil, mud, gypsum, cement, plastics, refractory materials, alumina, and polymer materials.

Product Name: Coal Moisture Content Tester

Product model: LXT-160

Product brand: Recht

Product principle of coal moisture content tester

The LXT-160 coal moisture content analyzer is developed and produced by Shenzhen Laixite Instrument Equipment Co., Ltd. The instrument consists of a weighing unit and a heating unit, and is based on the principle of drying loss to determine the moisture content of the sample. The moisture detector records the initial weight of the sample through an internally integrated weighing system, and then uses a tungsten halogen ring light source to heat the sample. The weighing system monitors and records the weight of the sample in real time. When the specified requirements are met, the measurement automatically stops and the final weight of the sample is recorded. The coal moisture content analyzer compares the initial weight value with the final weight value, and automatically converts the difference in sample weight into moisture content and solid content. The Lechte moisture analyzer is a reliable choice for testing the moisture content of samples, and the product complies with the national standard GB/T 29249-2012 electronic weighing drying method moisture analyzer.

Product functions of coal moisture content tester

The Lechte LXT-160 coal moisture content analyzer has a reasonable structural design, adopts an advanced measurement operating system, and has functions such as automatic weighing, automatic accuracy, Chinese English language switching, real-time measurement curve, and multiple testing mode selection. The traditional oven drying method uses air convection to heat the sample, which heats the sample slowly and requires a longer measurement time. The Lechte moisture detector uses a specific wavelength ring light source for drying, which is a further development of infrared drying method. During the testing process, the sample directly absorbs the thermal radiation emitted by the halogen light source to achieve rapid heating effect. During the drying process, the moisture detector continuously measures and displays the percentage of lost moisture in the sample in real time. The LXT-160 coal moisture analyzer can quickly measure the moisture content of the sample within a few minutes, ensuring fast response time for quality control and process control. Whether in busy laboratories or harsh production environments, a compact design saves space, while a sturdy structure ensures the long service life of the instrument. The coal moisture content analyzer comes with a data storage function, making it easy to access historical records; The instrument has communication function and comes standard with RS232 communication interface, making it convenient for real-time printing of results; The standard USB interface can be connected to a computer for operation, enabling software analysis of moisture data and powerful data processing capabilities, achieving technological breakthroughs in software and hardware. Lechte Instruments provides precise moisture measurement instruments and comprehensive moisture solutions for enterprise users. Accurate moisture results can effectively guide user production, improve product quality, and reduce enterprise costs. The Lechte moisture detector is used in many industries and is also an ideal instrument for the moisture detection industry.

Technical parameters of coal moisture content analyzer

Weighing range: 0-160g

Weighing accuracy value: 0.001g

Moisture readability: 0.001%

Moisture determination range: 0.001-100%

Weighing sensor: imported sensor

Temperature range: from initial to 240 ℃

Heating light source: specially designed circular heating light source

Heating program: fast

Test modes: automatic, timed, manual, phased

Timed time range: 1-360min (expandable)

Display 12 parameters: moisture%, solid content%, moisture curve, weight curve, temperature curve; Test duration, constant weight time, measurement mode, set temperature, measurement temperature, initial weight value, final weight value

Display language: Switch between Chinese and English

Data storage: Store the last 50 sets of measurement data (expandable)

Display curves: Simultaneously display three test curves (including moisture M, weight W, temperature T)

Sample disk size: diameter 100 (mm)

Display screen: 7-inch capacitive touch screen display

Communication interface: standard RS232 communication interface and standard USB interface, computer data analysis software (not included in the factory, optional accessories)

Dimensions: Length 390 * Width 220 * Height 170 (mm)

Net weight of the instrument: 3.65kg

Advantages of Coal Moisture Content Tester

1. The instrument has a reasonable structural design and patented technology in appearance;

2. It has the advantages of fast measurement, convenient operation, and reliable data;

3. A brand new measurement system with language switching between Chinese and English, fast and professional;

4. The operation interface displays three curves simultaneously, including moisture M, weight W, and temperature T;

5. The display screen adopts a 7-inch capacitive touch screen, which is intuitive, clear, and responsive;

6. The instrument comes with a data storage function, which can store the last 50 sets of measurement data for easy access to historical records;

7. The instrument has communication function and comes standard with RS232 communication interface, making it convenient for real-time printing of results;

8. The instrument has powerful data processing capabilities, with a standard USB interface that can be connected to a computer for software analysis of moisture data. The software interface includes functions such as measuring curves, sample names, sample weights, testing temperatures, testing times, record queries, printing of experimental data records, and exporting records;

9. Display 12 parameters, including moisture%, solid content%, moisture curve, weight curve, and temperature curve; Test duration, constant weight time, measurement mode, set temperature, measurement temperature, initial weight value, final weight value;

10. The instrument has four testing modes, including automatic, timed, manual, and stage measurement. Stage measurement enables testing of the same sample at different temperature stages, achieving multiple technological breakthroughs in the industry;

11. Using a specially designed circular heating light source, the sample is heated more evenly, dried more thoroughly, has stronger penetration ability, and measures faster.

12. Imported weighing sensors solve weighing problems such as temperature drift and time drift, improving measurement accuracy.

13. The temperature control system adopts imported high-sensitivity temperature control components to ensure the accuracy and controllability of temperature during the testing process.

14. Zero consumables during use, stainless steel sample tray, reusable, energy-saving and environmentally friendly.

15. Easy to operate, follow the touch screen operation instructions to master, no training required, laboratory or production line personnel can operate independently.

16. A comprehensive after-sales service system to promptly and quickly address customer feedback issues.

Operating Instructions for Coal Moisture Content Tester

(1) Place the weighing tray on the load-bearing bracket using a bracket and set it to zero;

(2) Weigh an appropriate amount of uniform sample and spread it flat on the weighing plate;

(3) Sampling completed, close the heating device;

(4) Wait for the weight to stabilize, tap the "Test" icon, and the instrument will start testing;

(5) Wait for the automatic completion of the measurement, display the moisture measurement results, and record the data;

(6) Clean the sample, return to the weighing interface, and prepare for the next measurement.

(7) The instrument comes with built-in data storage, making recording and viewing more convenient.

(8) USB communication interface, can be connected to a computer to store data.

Online inquiry