EPS emergency power supply

product overview

EPS (Emergency Power Supply) is a centralized emergency power supply that aims to provide power supply for primary load equipment such as emergency lighting, accident lighting, and fire protection facilities. It provides an independent circuit emergency power supply system that complies with fire safety regulations. This system can provide emergency power supply in emergency situations, to solve lighting power needs or to replace generator sets to form a second power source, or to be used in situations where a third power source is required.

EPS emergency power supply mainly adopts SPWM (alternating current pulse width modulation) technology, and the system mainly includes rectifier charger, battery pack, inverter, interconnection device, etc., among which the inverter is the core. The function of a rectifier is to convert alternating current into direct current, providing power to the battery and inverter module; The function of an inverter is to convert direct current into alternating current, providing stable and continuous power to the load equipment; The mutual switching device ensures smooth switching of the load between the mains power and the inverter output; The system controller monitors the entire system in real-time and can issue alarm signals. Generally, the switching time from grid power supply to EPS emergency power supply and from EPS power supply to grid power supply is not more than 0.1-0.2 seconds. When the power grid supply is normal, the EPS emergency power supply is in a charging saturation state (entering a float charging state), with power consumption less than 0.1% of the nominal capacity. At the same time, it can be connected to a computer or modem through a serial port to achieve microcomputer monitoring and remote monitoring of the power supply system.

EPS emergency power supply can be divided into three categories according to its purpose: emergency lighting, hybrid power, and power frequency conversion. Mainly used for power supply and fire protection in various types of buildings; Hospital safety power supply; Power supply for highways, tunnels, subways, light rails, and civil airports in the transportation system; Power supply of the power system; Power supply for various types of production and experimental equipment that cannot be powered off. It is a high-quality power supply that can provide pure sine waves to load devices.

Naming rules

Parameters

System composition diagram

Functional Features

Controlled by a microprocessor, it has a power on self-test function.

Use Mitsubishi's intelligent power module from Japan.

SPWM pulse width modulation technology, sine wave output.

Fully automatic high power factor charger.

LCD display, alarm function, historical fault record query.

Single battery inspection.

Can be linked with fire protection and remotely monitor RS232/485.

Three phase power supply can withstand 100% load imbalance.

Static, no noise, no smoke exhaust, and no fire hazards.

Automatic switching, capable of achieving unmanned operation.

Energy saving, low power consumption when not providing emergency power supply.

Stable performance, safe and reliable, long service life.

Compared to generator sets, the overall cost is lower.

Product execution standards

GB17945-2000 Fire Emergency Lighting Fixtures.

GB/T14048.1-2000 General Principles for Low Voltage Switchgear and Control Equipment.

GB/T4942.2-1993 Degrees of Protection Provided by Enclosures for Low Voltage Electrical Appliances.

GB/T3859-1993 Application Guidelines for Semiconductor Inverters.

YD/T777-1999 Communication Inverter Equipment.

GB16806 Fire linkage control equipment.

IEEE446-1995 Emergency and Backup Power Systems for Industrial and Commercial Fields.

CSA282 emergency power supply for buildings.

QB/SPS 21-2004 Se series emergency power supply.

YTEP-L series emergency lighting power supply

The YTEP-L series products are mainly emergency power supply devices that provide centralized power supply for emergency lighting places, suitable for various lamps (metal halide lamps, sodium lamps, fluorescent lamps, incandescent lamps, etc.), and also suitable for power supply of general electrical equipment.

YTEP-P series three-phase emergency power supply

The YTEP-P series products are mainly used for emergency power supply of fire-fighting facilities, primary loads, or other loads. In addition to being used for emergency lighting and accident lighting, it is also suitable for inductive loads or mixed power supply such as fire elevators, rolling shutter doors, fans, water pumps, sprinkler pumps, water supply pumps, etc.

When the load is a rolling shutter door, because the rolling shutter doors in high-rise buildings do not start simultaneously, the capacity of EPS should not be less than three times the total capacity of the rolling shutter door motors that start simultaneously. Due to the low power consumption for the operation of the rolling shutter door, the battery configuration can be correspondingly reduced if only the rolling shutter door is installed. Generally, a 20 minute backup time with EPS capacity is available.

When the load is an elevator, the elevator drive motor should have frequency conversion function, and the capacity of EPS should be 1:1 of the total capacity of the elevator.

When the load is a water pump or fan, without any measures such as frequency conversion or star delta voltage reduction starting, the capacity of EPS should be more than 5 times the capacity of the motor working simultaneously. If there is variable frequency starting, the capacity of EPS is 1:1 of the total capacity of motors working simultaneously. If the star delta voltage is reduced and started, the capacity of EPS is more than three times the total capacity of motors working simultaneously.

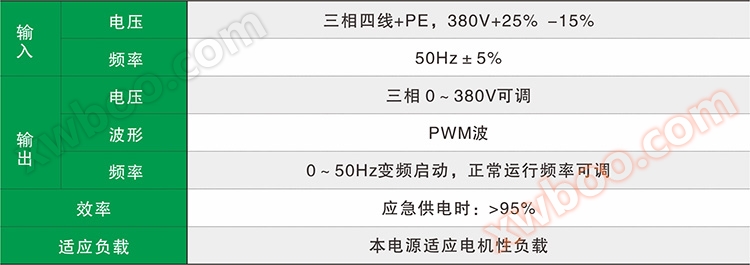

YTEP-F series variable frequency three-phase emergency power supply

The YTEP-F series products mainly provide a variable frequency three-phase emergency power supply system for fire protection facilities or motors in primary loads with only one power source, to solve the emergency power supply of motors and the impact on power supply equipment during the starting process. For example, electric motors for water pumps, fans, or other equipment.

The load can be fire protection facilities such as fans, pumps, or primary loads.

The capacity of the load is 1:1 with the capacity of the EPS, without considering the margin, and there is no need to increase the voltage reduction starting function, as the F series EPS already has a variable frequency starting function.

The start and operation of the load are also controlled by the start signal connected to EPS.

The output of EPS must be directly connected to the motor of the load, and the original control cabinet of the load should be removed and not used.

The F series EPS is divided into single inverter single load type, single inverter one use one backup type, dual inverter one use one backup type, or two use one backup type. Please select the appropriate type according to the order of load design and usage scenario.