|

WS (SX) - Series Bimetallic (Electric Contact) Temperature GaugeSuitable for on-site detection at medium and low temperatures, it can directly measure the temperature of liquids, gases, and vapors, with no mercury hazard, clear indication, robustness, and shock resistance. All instruments are made of stainless steel material, which has good waterproof and anti-corrosion properties. Electric contact bimetallic thermometer is an instrument suitable for on-site detection and automatic control of medium and low temperatures. It can directly measure the temperature of gases and automatically control or signal the temperature changes of the measured medium. This series is widely used in industries such as petroleum, chemical, metallurgical, textile, and food. |

|

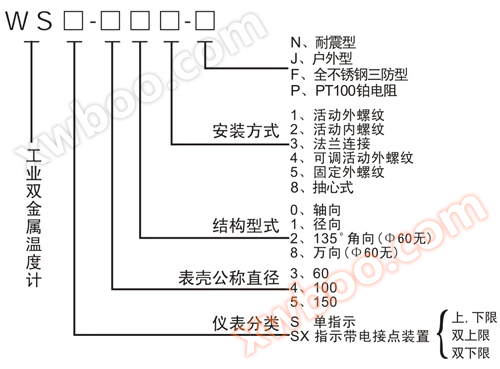

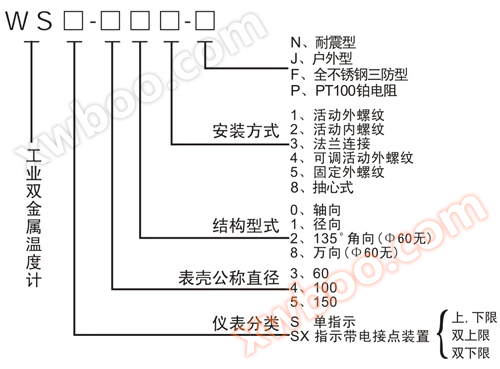

Model indication

|

|

|

|

Technical Specifications

|

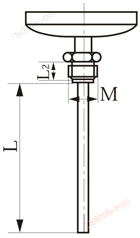

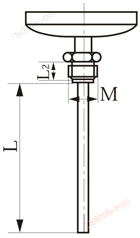

| Unit: mm |

| model |

nominal diameter |

Measurement range ° C |

Grid value ° C |

Insert length

L |

Diameter of protective tube

d |

install thread

M |

| WSS-3 port |

60 |

0~50

0~100

0~150

0~200

0~300

0~400

0~500 |

1

2

2

5

5

10

10 |

75;100;

150; 200;

250; 300;

400; 500; |

6 |

M16×1.5 |

| WSS-4口 WSSX-4 口 |

100 |

10 |

27×2 |

| WSS-5 port |

150 |

10 |

|

Accuracy: ± 1.5%

Time constant: not greater than 40s

Protection tube pressure resistance: 6.3MPa

Rated power of electrical contact: 20VA (no inductive load)

Maximum operating current: 1A

Continuous current: 0.6A

Maximum operating voltage: 380VAC, 220VDC

Instrument straight standard: JB/T8803-1998 |

|

|

Installation method

|

|

|

|

|

|

| Active external thread (1) |

Active internal thread (2) |

Flange connection (3) |

Adjustable active external thread (4) |

Fixed external thread (5) |

|

|

WSSX wiring diagram:

|

|

| 1. Public line |

2. Upper limit |

3. Lower limit |

4. Grounding |

|

|

| model |

Overall dimensions |

| D |

H |

L |

L1 |

L2 |

L3 |

M |

| WSS-30 □ |

60 |

/ |

75;100;

160; 200;

250; 300;

400; 500;

~1000. |

62 |

12 |

|

16×1.5 |

| WSS-31 □ |

46 |

60 |

| WSS-32 □ |

44 |

55 |

| WSS-40 □ |

100 |

/ |

72 |

16 |

27×2

G½

ZG½

NPT½ |

| WSS-41 □ |

46 |

94 |

| WSS-42 □ |

44 |

82 |

| WSS-48 □ |

58 |

64 |

| WSS-50 □ |

150 |

/ |

72 |

16 |

| WSS-51 □ |

46 |

112 |

| WSS-52 □ |

44 |

82 |

| WSS-58 □ |

58 |

64 |

| WSS-401 □ |

100 |

/ |

72 |

16 |

42 |

27×2 |

| WSS-411 □ |

46 |

94 |

| WSS-421 □ |

44 |

82 |

| WSS-481 □ |

58 |

64 |

|

|

|

|

|

| WSS-□ 01 |

WSS-□ 11 |

WSS-□ 21 |

WSS-□ 81 |

|

|

|

|

|

| WSSX-□ 401 |

WSSX-□ 411 |

WSSX-□ 421 |

WSSX-□ 481 |

|

Application of thermometer sleeve

When the process involves high pressure, high flow rate, or corrosive conditions, and the protective tube of the bimetallic thermometer itself is not suitable for such conditions, as well as when it is required that the process pipeline or equipment be a closed system before the instrument is installed, a thermometer sleeve should be used to ensure safety and normal operation. For medium and low pressure media, it is advisable to use straight or conical drilled tube thermometer sleeves; For situations where the flow rate of the measured medium is high or where high strength is required for the thermometer sleeve, a conical drilling sleeve should be selected; For situations where reducing resistance or decreasing thermal response time is required, a stepped thermowell can be used. |

|

Specification of thermometer sleeve

|

| Sleeve form: straight, conical, stepped |

| Types of casing: seamless steel pipe, integral drilled pipe |

Casing diameter: Inner diameter Ø 6~Ø 16 (integral drilling pipe)

Outer diameter Ø 12~Ø 30 (seamless steel pipe) |

Total length of casing: Whole drilling pipe: ≤ 1000mm

Seamless steel pipe: as needed |

| Sleeve material: 304, 316, titanium, Hastelloy, Monel alloy, high-temperature tube, etc |

| Installation forms of casing: straight thread, tapered thread, welded type, flange type |

|

|

|

|

|

|

Model representation of thermometer sleeve

|

|

|

| code name |

annotation |

| W |

Temperature Instrument

|

| TG |

casing

|

|

1 |

Type of casing structure

|

| Seamless steel pipe type (split welding) |

| T-shaped drilling pipe type (integral drilling) |

| P cone drilling tube type (integral drilling) |

| S-shaped drill pipe type (integral drilling) |

|

2 |

Installation connection method

|

| G straight thread |

| N-cone thread |

| W welding |

| F flange |

|

| If there are any other requirements, they can be customized after our company confirms and clarifies them |

|

|

Ordering Instructions |

| Model/structural form/connection form/total length/insertion depth/connection thread |

| Template representation |

|

| Textual expression |

| Bimetallic thermometer sleeve, tapered sleeve with tapered thread connection Z3/4 "total length L x insertion depth E=200 * 150 |

|

|

Overall dimensions

|

|

Note:

| e: Insertion depth - determined by the user based on the size of the device or tubing |

| T: Extension length - When equipment or pipelines have insulation layers, extension length can be provided as needed |

| L: Total length of casing |

|

|

|

Safety Warning

For safety reasons, please choose the correct model of product. Improper selection or use of the product may result in property damage or personal injury. The system designer and user are fully responsible for selecting the correct product and using it in the correct way |