Characteristics

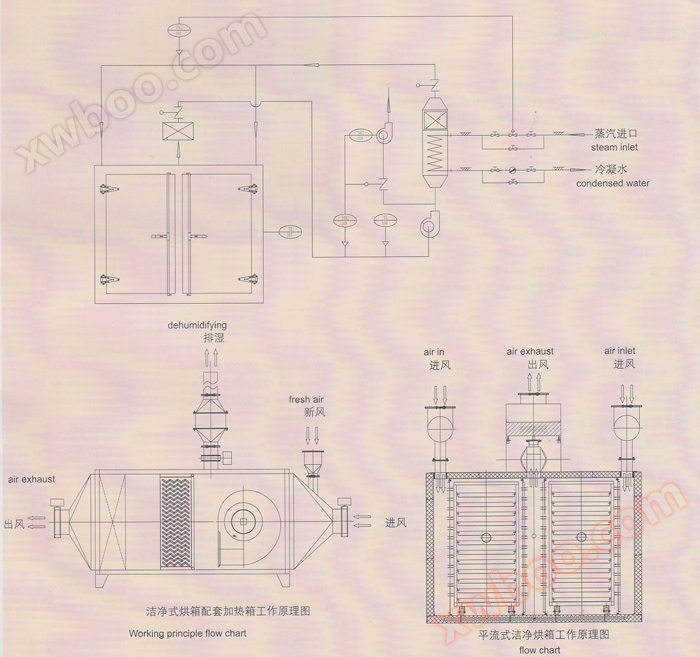

1. Choose a centrifugal fan with high air volume and pressure as the circulating fan for forced ventilation, which can accelerate the drying speed of materials and ensure the uniformity of material drying.

2. The air inlet of the oven is divided into two stages of filtration. The fresh air inlet is a sub high efficiency filter, which makes the fresh air reach 100000 level. After heating, each cycle of hot air is equipped with a high-temperature and high-efficiency filter for filtration, making the hot air entering the drying oven reach a cleanliness level of over 10000 level, ensuring the cleanliness of the drying process;

3. The system is equipped with a forced dehumidification all stainless steel dehumidification fan, and the humidity inside the system is collected by the system's LC program module for intelligent control: according to the signal provided by the humidity control instrument, the air door actuator of the dehumidification port is controlled to execute the air door, and at the same time, the dehumidification fan is controlled. The dehumidification fan outputs the corresponding frequency output by the frequency converter based on the humidity signal size to achieve the best dehumidification effect and achieve reasonable dehumidification.

4. The inlet and outlet of the oven are equipped with automatic control dampers, which are automatically closed when the equipment is stopped to cut off the connection between the purification area and the auxiliary equipment;

5. The air in the circulation system enters from both sides of the main unit and is concentrated in the middle for exhaust, reducing the temperature difference between the left and right sides of the oven compared to conventional designs. The inlet and outlet air equalization devices use quick installed unequal ratio punching plates, and multiple sets of punching plates with unequal ratios are designed according to the guiding rules of the air volume and pressure of the inlet and outlet air as distribution devices for inward hot air to achieve smaller temperature differences. The fixing method between the air equalization mesh plate and the main unit adopts a quick installation fixing method, which can quickly clean and wash the inlet and outlet air ducts to ensure the hygiene and cleanliness inside the box

6. The equipment is equipped with online cleaning ports on the inlet and outlet ducts that can cover the entire system, achieving fast and convenient online cleaning functions:

7. The equipment heating system (heater, high-temperature high-efficiency filter) is external and concentrated in a sealed stainless steel box, with good insulation effect and high hygiene cleanliness. In addition, the high-temperature high-efficiency filter is a drawer style quick installation structure, which can be quickly cleaned and replaced; The supporting connectors and system connections adopt butterfly screw quick installation design, which is convenient for maintenance and inspection:

8. Conduct pressure difference detection and real-time monitoring of high-temperature and high-efficiency filters, and provide pressure difference alarm function to ensure the cleanliness and safety of the system:

9. There are 2 quick verification ports on the device host, which facilitate the verification of temperature, humidity, etc. during the working process.

10. The control system is equipped with a three-level password function and a USB interface.

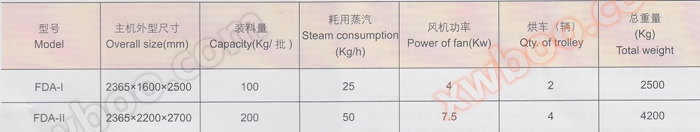

Technical Parameter

Process Flow Diagram