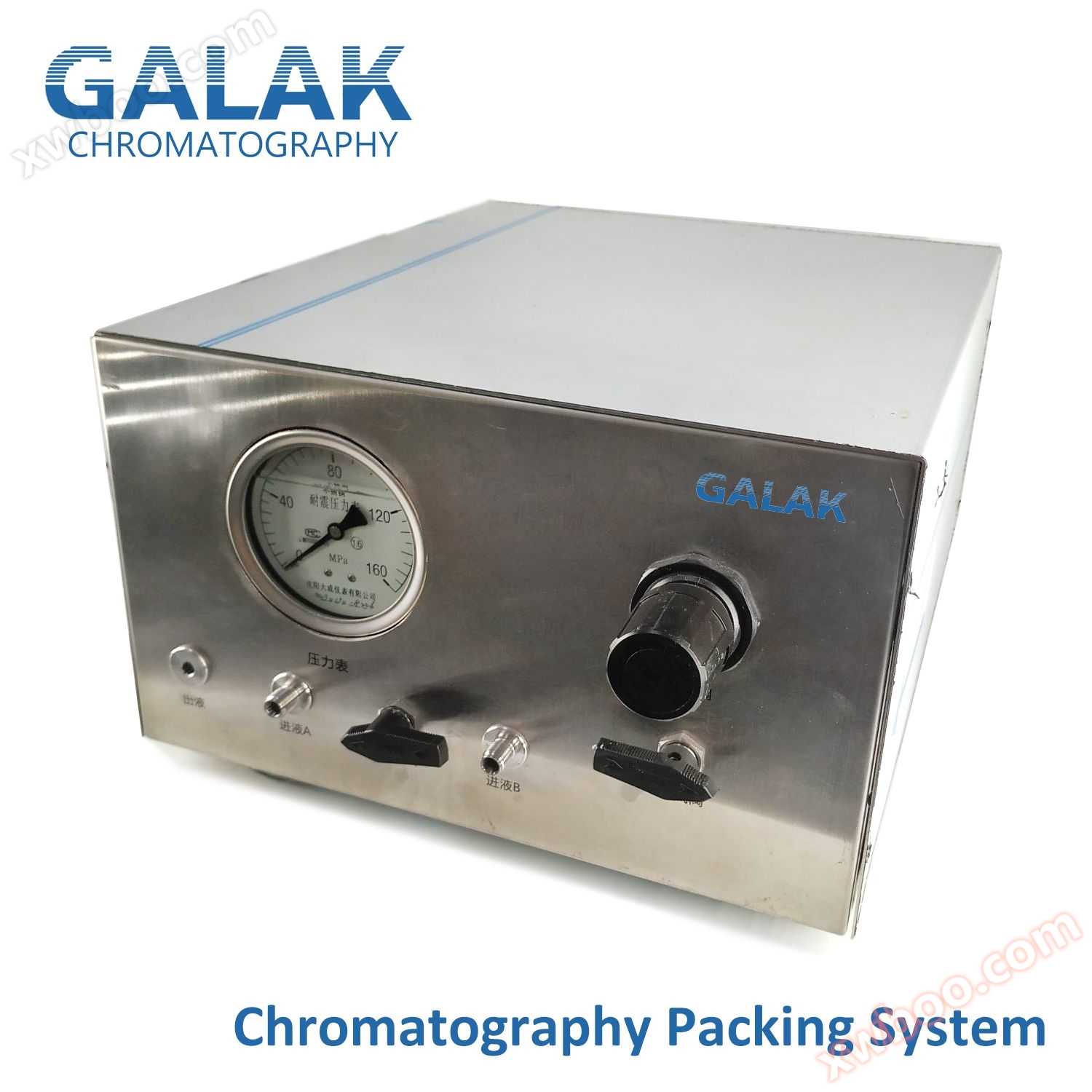

The GLK column loading machine (utility model patent, patent number:. 6) can load conventional analysis, semi preparation, and preparation liquid chromatography columns required for high-performance liquid chromatography. The product comes in two models: GLK1000 and GLK2000. The GLK1000 model is tailor-made for laboratory routine analysis columns, suitable for loading commonly used silica gel and polymer fillers in analysis columns. The GLK2000 model has stronger and more stable power, covering the loading of analysis to preparation of liquid chromatography columns.

The entire column installation system mainly includes compressed air supply system, column installation machine, homogenization tube, and homogenization tube rotary car (optional).

The compressed air supply equipment includes an air compressor, an oil-water separator, and a condenser. The column installation machine is powered by compressed air, therefore it requires pure and dry compressed air. Equipped with an oil-water separator can remove oil from compressed air, and an air condenser can remove moisture from compressed air.

The pressure amplification factor of the pneumatic booster pump in the GLK1000 column loading system is half that of the GLK2000 model, and the flow rate of the pressurized liquid is relatively low, making it more suitable for the loading of conventional analytical columns in the laboratory. For the loading of preparation columns with an inner diameter exceeding 10mm, it is necessary to choose the GLK2000 column loading system with higher pressure, greater stability, and faster flow rate.

The preparation columns with inner diameters of 30mm and 50mm require a large amount of homogenate for filling, therefore, larger homogenate tubes are needed. The large and bulky homogenization tube, combined with the weight of the column tube itself and various joints, makes the operation time-consuming and laborious. Galak specially designed a homogenizer tube rotary car based on these issues (utility model patent, patent number:. 7). During the column installation process, the homogenization tube can be placed on a chassis that can be freely moved indoors, and the homogenization tube fixed in the fixed ring can rotate 360 ° in a plane perpendicular to the rotation axis, making it easy to change the column installation position and direction. It saves manpower and makes column installation simpler.

At present, the column installation system has been sold in well-known enterprise research institutes such as the Chinese Academy of Sciences in Beijing, Dalian Institute of Physical Chemistry, Sichuan University, Zhengzhou University, Dalian Ocean University, Southern University of Science and Technology, Hebei University, and Qingdao University.

Technical Specifications

| model |

GLK1000 |

GLK2000 |

|

Suitable for loading chromatographic column types |

Inner diameter 4.6mm |

Inner diameter 4.6-50mm |

|

Maximum rated output pressure |

9800psi |

15000psi |

|

maximum flow |

3.3L/min |

3.3L/min |

|

Output horsepower |

1.5hp |

2.2hp |

|

drive head |

Single pump head |

|

matching products

|

serial number |

name |

quantity |

|

1 |

GLK2000 Column Installation System |

1 unit |

|

2 |

Compressed air purification system |

1 set |

|

3 |

air compressor |

1 unit |

|

4 |

Homogenization tank |

1 set |

|

5 |

Analysis and preparation of column tubes |

one set each |

|

6 |

Homogenizer tank rotary cart |

1 unit |