Intelligent turbine control system

Committed to providing safer, more efficient, and more economical intelligent turbine control systems, Keyuan Intelligence fully utilizes advanced technologies such as intelligent control, diagnostic technology, and big data to expand its conventional control functions. It integrates process control, safety interlocking, status monitoring and diagnostic analysis, and intelligent warning, improving the system's automation level and monitoring performance, and reducing equipment failure rates.

Product Features

-

Application Enhancement:

By combining remote diagnosis, big data analysis, intelligent control system and other functions, remote monitoring and analysis of unit operation can be carried out, effectively improving operational efficiency, extending equipment life, and reducing maintenance difficulty.

-

Operation layer:

By using a 3D interface and 2D/3D linkage function, the monitoring field of view for operators has been expanded; A semi physical online simulation system can be built to connect with online data in real-time, allowing for faster improvement of personnel capabilities.

-

Process optimization control:

By integrating DEH, ETS and other systems, increasing thermal stress calculation and management, and optimizing control of turbine island operation, the unit can automatically and safely complete the start-up or shutdown process.

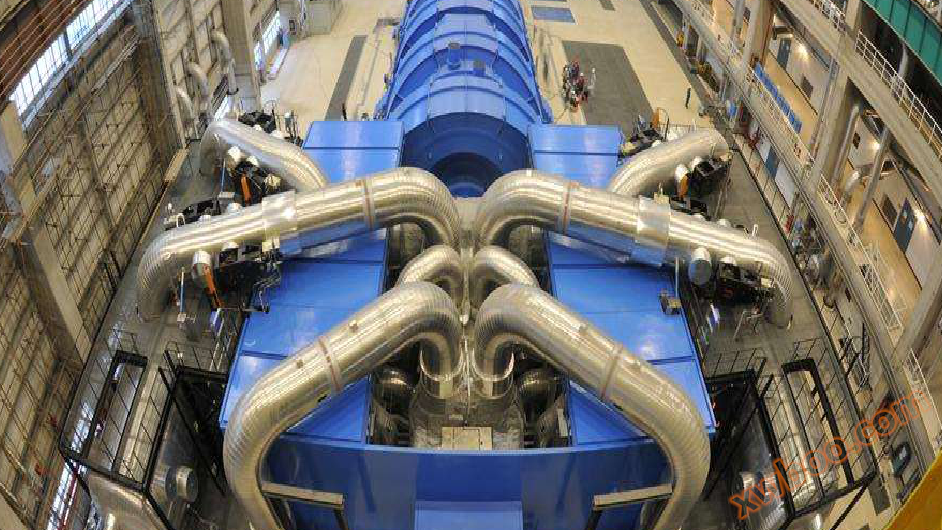

Function Architecture

Product advantages

Product Value

classic case

Guangda Environmental Protection Energy (Jiangyin) Co., Ltd. is designed with a total daily processing capacity of 1000 tons of household waste, equipped with two 500 ton/day incinerators and one 25MW steam turbine unit. At the same time, it will demolish the old and build a new garbage leachate treatment facility with a daily processing capacity of 1000 tons, with a total investment of approximately RMB 580 million.

At 12:30 on May 1st, after the operator issued the cold start command at the operation station, the automatic start stop system of the steam turbine automatically completed the process of speed increase, warm-up, grid connection, load carrying, and load increasing without human intervention, and automatically coordinated the actions of various functional subsystems according to requirements. The entire process does not require manual intervention, greatly improving the automation level of steam turbine operation and enhancing the reliability of steam turbine operation. At 13:38, the steam turbine successfully completed automatic grid connection and entered a stable operating state. Subsequently, automatic control debugging was carried out for multiple working conditions such as shutdown without shutdown and hot start, all of which were automatically implemented as required and met the established requirements.

The successful renovation of the Guangda Jiangyin Phase III project marks the first intelligent renovation project of a domestic waste incineration power plant, and also the first one key start stop renovation project of a waste incineration power turbine in China, achieving complete success.