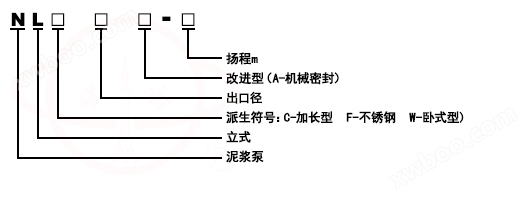

Model Meaning

Product Introduction

The NL vertical mud discharge pump is a single-stage single suction vertical centrifugal pump, which is mainly composed of volute, impeller, pump seat, pump casing, support cylinder, motor seat, and electric motor. The snail shell, pump seat, motor seat, and impeller nut are cast from pig iron, with good corrosion resistance and convenient processing technology.

The impeller consists of three single chord curved blades, which are semi enclosed and made of malleable cast iron, resulting in high strength and corrosion resistance; Easy processing, good passability, and high efficiency.

In order to reduce weight and cutting volume, the pump shaft is made of high-quality carbon steel cold drawn round steel. The pump seat is equipped with four skeleton oil seals and shaft sleeves to prevent shaft wear and extend the service life of the shaft.

The NL mud pump can be used vertically or obliquely, with a small footprint. The volute needs to be buried in the working medium for easy start-up and does not require water intake. The rotation direction should be clockwise when viewed from the tail of the motor.

There are various specifications for the length of the switchboard, so that users can choose according to their specific needs.

application

1. The NL vertical mud discharge pump is mainly used in rural areas for pumping and irrigating river mud, feces, river water, and slurry feed. It can replace shoulder carrying and human carrying, and is also used for drainage and drought resistance. It can also be used for truck shore, river mud, and fertilizer production. It can also be used as a simple mobile fire pump in rural areas, as well as for fish farming with water clearing ponds, fish pond oxygenation, etc.

2. The mud pump produced by our factory can be used in industries such as municipal, chemical, printing and dyeing, pharmaceutical, shipbuilding, casting, food, etc. to extract thick liquids, polluted liquids, paste like bodies, quicksand, and flowing sludge from urban rivers. It can be used in coal mines to remove fluids containing mud blocks and small gravel.

3. If combined with high-pressure pumps and water guns to form a hydraulic mechanized earthwork unit, it can be used for soil excavation and transportation in land leveling, river channels, ponds, air defense, underground and other projects.

working conditions

1. The NL vertical mud discharge pump is a single-stage single suction centrifugal pump used in mining, papermaking, printing and dyeing, environmental protection, graphite, mica, gold, ceramics, refining, petroleum, chemical, farm, salt field, iodine field, dyeing, brewing, food, fertilizer, coking plant, construction, marble plant, gold mine, mud, quicksand, mud pond, sewage pond, and polluted liquid to suction thick slurry, loading and suspended solids in sewage operations. It can also be used for coal mine drainage and fluids containing mud blocks.

2. If combined with high-pressure pumps and water guns to form a hydraulic mechanized earthwork unit, it can be used for excavation and transportation of small water conservancy projects such as land leveling, dredging and chiseling of rivers and ponds, as well as urban air defense projects.

3. Fish farming is used for carrying water to clear ponds, increasing oxygen in fish ponds, etc.

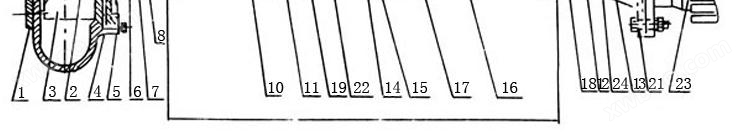

Structure diagram

|

|||||

Serial Number |

Type/Item Name |

Serial Number |

Type/Item Name |

Serial Number |

Type/Item Name |

1 |

Mesh cover |

9 |

Water outlet elbow |

17 |

Supporting cylinder |

2 |

IMPELLER NUT |

10 |

Pump shaft |

18 |

Bearing cap |

3 |

impeller |

11 |

bearing |

19 |

Driven coupling |

4 |

case of pump |

12 |

Driven coupling |

20 |

motor base |

5 |

pump base |

13 |

Active coupling |

21 |

Motor seat C |

6 |

o-ring |

14 |

Connecting cylinder |

22 |

Active coupling |

7 |

oil seal |

15 |

bearing housing |

23 |

motor |

8 |

shaft sleeve |

16 |

coupling shaft |

24 |

Elastic block |

performance parameter

model |

Speed n r/min |

Traffic Q m3/h |

Head H m |

Efficiency n % |

Motor Power KW |

Total length of vertical pump mm |

Pump weight kg |

NL50-8 NL50A-8 |

1450 |

20-30 |

8-9 |

42 |

1.5 |

1310 |

63 |

NL50-12 NL50A-12 |

1450 |

25-38 |

12-14 |

41 |

3 |

1310 |

80 |

NL50-24 NL50A-24 |

1450 |

25-38 |

20-24 |

41 |

5.5 |

1430 |

152 |

NL65-16 NL65A-16 |

1450 |

50-60 |

15-18 |

42 |

5.5 |

1430 |

152 |

NL65-25 NL65A-25 |

1450 |

50-60 |

20-25 |

42 |

11 |

1510 |

265 |

NL76-9 NL76A-9 |

1450 |

50-70 |

9-10 |

42 |

3 |

1350 |

90 |

NL76-16 NL76A-16 |

1450 |

50-70 |

14-16 |

42 |

5.5 |

1430 |

152 |

NL76-20 NL76A-20 |

1450 |

50-70 |

18-20 |

42 |

7.5 |

1430 |

155 |

NL80-8 NL80A-8 |

1450 |

60-70 |

7-9 |

56 |

4 |

1400 |

120 |

NL80-12 NL80A-12 |

1450 |

80-120 |

11-13 |

56 |

7.5 |

1430 |

145 |

NL80-25 NL80A-25 |

1450 |

80-100 |

25 |

56 |

11 |

1550 |

270 |

NL100-7 NL100A-7 |

1450 |

70-80 |

6-8 |

61 |

4 |

1430 |

130 |

NL100-10 NL100A-10 |

1450 |

100 |

10 |

61 |

7.5 |

1450 |

160 |

NL100-16 NL100A-16 |

1450 |

80-100 |

15-17 |

61 |

15 |

1510 |

270 |

NL100-25 NL100A-25 |

1450 |

80-100 |

20-25 |

61 |

18.5 |

1690 |

350 |

NL150-12 NL150A-12 |

1450 |

100-150 |

11-13 |

66 |

18.5 |

1690 |

350 |

NL150-16 NL150A-16 |

1450 |

120-180 |

15-20 |

68 |

22 |

1690 |

370 |

Precautions for use

1Our factoryThe power supply must be three-phase four wire system. If there is no grounding wire, it must be installed to prevent leakage. When working, it is necessary to install circuit fuses and switches that match the motor nearby to prevent the motor from being burned out when debris gets stuck in the impeller.

2. This pump can be operated without installing any basic equipment when in use, as long as it is firmly inclined and tied with ropes if necessary to prevent accidents. After exceeding the limit, the rotation direction of the motor must be checked and must not be reversed for more than one minute.

3. When the liquid being sucked contains a lot of weeds, iron wires, wooden strips, bricks and other debris, it must be removed as much as possible in advance, and methods such as adding wire baskets can be used to prevent debris from being sucked into the pump, causing accidents such as impeller damage, jamming and pipeline blockage.

4. The pump body should be given short-term suction after absorbing mud and other pollutants, in order to flush the pump body and the interior of the pipeline.

5. When working outdoors, the motor should be equipped with a protective cover to prevent rainwater and other substances from entering the motor.

6. It is advisable to hang the suction mud at the bottom of the river pool on a tripod and place it on a float or a general platform for mobile operations. During earthwork operations, the diameter of the soil blocks crushed by the high-pressure water gun should not exceed one-third of the suction port.

7. The conveying speed specified for NL mud pumps is a high conveying speed without pumping, and it is arbitrary to increase it; The use of reducing the speed is not limited, but the effect is significantly reduced.

8. This pump reduces the load when pumping thick mud, thick liquids, or high lift, long-distance mud, but cannot increase the load by changing the structure.

9. Normally running for about 1250 hours, regular maintenance of the pump should be carried out by disassembling the pump seat to check the bearings and sealing condition of the pump, cleaning and replacing the grease, and replacing the oil seal, shaft sleeve, and other parts if necessary. Please refer to the installation for maintenance and replacement of parts precautions. (Use mechanical seals to run the pump for about 3500 hours for regular maintenance).

10. When the use is stopped for a long time, the snail shell should be disassembled, the parts should be wiped dry, and a thin layer of oil should be applied to the relative motion joint surface. It should be stored in a dry place for future use.

Disassemble and install

1disassemble

1. Disassemble the motor or fixing plate, and remove the water outlet pipe.

2. Disassemble the snail shell and impeller nut, gently pry the back of the impeller, and remove the key impeller.

3. Dismantle the driven half coupling, then remove the key, and finally detach the motor base from the support cylinder.

4. Remove the pump seat and support cylinder bolts to separate them.

5. Remove the shaft sleeve and bearing from the shaft.

IIinstall

1. Inspect all parts for defects, apply a layer of thin butter on both sides of all paper pads, and add two-thirds of the butter inside the bearings.

2. The skeleton oil filling must be filled with butter and placed in the pump seat before installing the bearings.

3. Install an O-ring seal inside the shaft sleeve and apply butter.

4. Install the bearing on the motor base, place a paper pad and oil stopper ring, install the shaft and support cylinder, and fix them with screws.

5. Put on the paper pad, install the bearing, shaft sleeve, key, pump seat, and impeller. Tighten the impeller nut and manually rotate the impeller to ensure flexible movement.

6. Place a paper pad onto the pump casing, secure it with screws, and install the filter screen. Then pull the impeller by hand and rotate it flexibly.

7. Install the key and the driven coupling on the pump shaft, and install the key and the active coupling on the motor shaft. Then fix the motor to the motor seat bolt. After installation, it is required that the axial clearance between the active coupling and the passive coupling should be 1-1.5 millimeters.

Fault analysis and troubleshooting methods

phenomenon |

cause |

Troubleshooting |

without ability open move give move change |

1. The power supply line has a broken circuit. 2. The voltage is too low. 3. There is no axial clearance between the two half couplings and they are stuck. 4. The impeller is stuck by debris. 5. The impeller is tightly attached to the snail shell. 6. The nut falls off and the flat key is damaged, causing the impeller to slip. 7. The coupling flat key is damaged. |

1. Check the blown fuse and wiring, and replace them. 2. Raise the voltage or wait for the voltage to rise before using it again. 3. Adjust the axial clearance between the two half couplings to 0.5 millimeters. 4. Remove debris. 5. Reinstall and separate the impeller and volute. 6. Install flat keys and nuts. 7. Replace the flat key. |

exceed burden lotus |

1. Improper assembly of various parts of the pump, difficulty in rotation, and foreign objects getting stuck. 2. Concentricity changes, bearing damage, shaft deformation. 3. Rotate in the opposite direction. 4. The head is too low and the flow rate is too high. |

1. Reinstall and remove foreign objects. 2. Correct the parts and replace the bearings. 3. Change the direction of rotation of the motor. 4. Try to avoid prolonged use. |

flow lining without foot |

1. The suction port is blocked, the mud pit is not deep enough, and the pump cannot suck up the mud and feces. 2. The mud pipeline is blocked. 3. The motor speed is lower than the rated speed. 4. The impeller is damaged. 5. The lift is too high and the conveying distance is too far. 6. Traveling in the opposite direction. 7. The leakage is significant. 8. There are debris around the impeller. 9. The medium is too thick or the supply is limited. |

1. Remove the obstruction at the suction port, move the pump, and bury the volute completely in the mud and sewage. 2. Inspect the pipeline and remove the obstruction. 3. Increase the motor speed. 4. Replace the impeller. 5. Reduce the head and shorten the conveying distance. 6. Change the direction of rotation of the motor. 7. Check the cause of the leak and replace the other component that caused the leak. 8. Remove debris. 9. Dilute the medium and increase the supply. |

Noise sound give quake move |

1. Friction between impeller and volute. 2. The bearing is damaged or has insufficient oil. 3. The pump shaft and motor are not concentric, and the shaft is bent. 4. The nut is loose. 5. There are debris in the snail shell. 6. There are hard objects in the working fluid. 7. There is air infiltration into the suction port. 8. The temperature of the liquid being pumped is too high. |

1. Check the assembly of the pump and adjust it. 2. Replace the bearings or add oil. 3. Align the center and calibrate the axis. 4. Tighten the nut. 5. Remove debris. 6. Control the scale of impurities entering the pump and tighten the filter screen. 7. Deeply embed the snail shell. 8. Reduce the temperature of the liquid. |