On a certain yield line, by3The worker completes the placement of adhesive bandages on the conveyor belt into the material slot and counts them at the same time. The customer hopes to produce robots on this production line to solve the existing problemsPoor hygiene, counting errors, low efficiencyWait for the problem and increase the speed to120-180piece/minute.

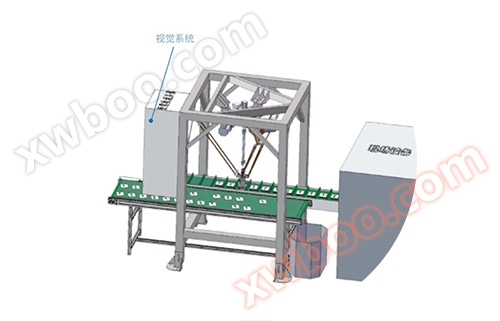

The adhesive tape is transported by a conveyor belt to the vision system for pose recognition, and the robot sequentially absorbs the pose information5After adjusting the angle, the film is placed in the empty material slot. The photoelectric detection equipment on the material slot detects whether the number of adhesive bandages in the slot meets the requirements. If the quantity is correct, it is transferred to the next station for boxing. If the quantity is incorrect, it will be removed from the production line and flow into the recycling box with different end effectors. According to different production capacity requirements, the robot can complete the processSingle piece picking and placing、Multiple consecutive pickups and single placementWaiting for different process requirements.

| Results after implementation | data |

| Reduce manpower | 3 people |

| Efficiency growth | 75% |

| takt time | >120 pieces/minute |

| defective rate | 0 |

| floor area | 7㎡ |

| Payback Period | 2 years |

This application can be widely used inMedicine, food3CElectronics and daily necessitiesWaiting for the industry.Nanjing Ruiyi Intelligent Technology Co., Ltd. can customize according to customer needs.

| Nanjing Ruiyi Intelligent Technology Co., Ltd |

| Address: No. 28 Fengshou Road, Dongshan Industrial Concentration Zone, Jiangning, Nanjing |

| Telephone: |

| Fax |

| For business cooperation, please contact | |||

|

Scan and add WeChat

|

||

Previous:Sorting robot metal gasket screening