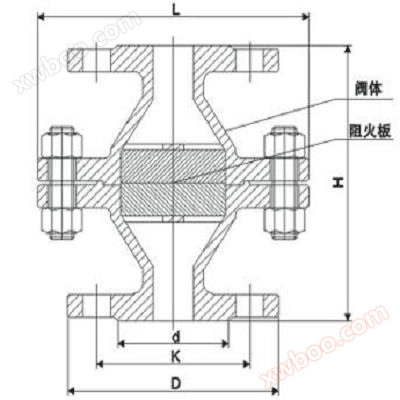

Model of propane pipeline flame arrester:GZW-P

Product Introduction: The propane pipeline flame arrester fully complies with the performance requirements of GB13347-92 "Fire Resistance Performance and Test Methods for Petroleum Gas Pipeline Flame Arresters".

The structure of the flame arrester is reasonable, and the flame arrester core is made of stainless steel material, which is corrosion-resistant and easy to clean. housingUsing a variety of materials including stainless steel, carbon steel, and cast steel, it can be fully utilized

Meet the needs of various process pipelines.

Flame arresterpurpose:Explosion proof flame arresters are used to transport flammable gases such as heating fuel gas, natural gas, liquefied petroleum gas, and coal mine gas

The pipeline network is also used for gas pipelines,To prevent the reverse propagation of flames in pipelines under normal circumstances and avoid sudden accidents, it has been tested and proven safe

Flame retardant, with a speed of 1425m/s and a maximum speed of 1605m/s

Flame arrester performance:

① The explosion resistance performance is qualified, and it can block fire every time for thirteen consecutive tests;

② Qualified fire resistance, heat-resistant, and no tempering for 1 hour.

The main material of propane pipeline flame arrester is:

Shell: Stainless steel 3040, 316, carbon steel WCB

Flame retardant core: stainless steel corrugated plate

Sealing ring: Nitrile rubber PTFE metal gasket

Flame arrestertechnical parameter:

Nominal pressure: PN1.0

~6.4MPa

Nominal diameter: DN50~DN300

Connection method: flange

Applicable media: oil products, various non corrosive or weakly corrosive gas media, etc

Applicable temperature: -20 ℃ to+440 ℃Standard for propane pipeline flame arresters:Flange standard:GB、HG、SH、HGJ、JB、ANSL、JIS

Waiting for standards. (User specified, please indicate pressure level)Execution standards:GB13347-92Fire resistance performance and testing methods of flame arresters for petroleum gas pipelinesThe lawSH/T3413-99

Fire resistance of petroleum and gas pipelines in the petrochemical industrySelection, Inspection, and Acceptance of InstrumentsHG/T20570.19-95The setting of flame arresters. Production, inspection, and acceptance standards for flame arresters:

SY/T0512-1996Fire arresters for oil storage tanksTest basis:GB5908-86

Performance and experimental methods of flame arresters for oil storage tanks.Flame arrester

|

Size: specifications |

DN pressure |

PN |

External connection dimensions (mm) |

|||||

|

Bolt |

K |

D |

DL |

L |

number |

|||

|

thread |

1.6 DN20

|

75 |

105 |

195 |

200 |

4 |

MPa |

|

|

M12 |

85 |

115 |

195 |

200 |

4 |

DN25 |

||

|

M12 |

110 |

150 |

245 |

240 |

4 |

DN40 |

||

|

M16 |

125 |

165 |

245 |

240 |

4 |

DN50 |

||

|

M16 |

160 |

200 |

280 |

250 |

8 |

DN80 |

||

|

M16 |

180 |

220 |

335 |

260 |

8 |

DN100 |

||

|

M16 |

240 |

285 |

460 |

360 |

8 |

DN150 |

||

|

M20 |

295 |

340 |

520 |

420 |

12 |

DN200 |

||

|

M20 |

355 |

405 |

580 |

430 |

12 |

DN250 |

||

|

M24 |

410 |

460 |

705 |

450 |

12 |

DN300 |

||

M24Flame arrester

Regular inspection and maintenance should be carried out:

1. The flame arrester should be inspected every six months to check whether the flame arrester core is blocked, deformed, corroded, etc.

2. The blocked fire-resistant layer core should be cleaned thoroughly to ensure that each hole on the core is unobstructed, and any deformed or corroded fire-resistant layer should be replaced.

3. When reinstalling the fire-resistant layer core, it should be ensured that the joint surface is tight and there is no air leakage.Shanghai Nanshi is a professionalManufacturer of propane pipeline flame arresters

The products produced by the company include breathing valves, flame arresters, fire-resistant breathable caps, fire-resistant vacuum pressure capsAluminum alloy ball valve, aluminum alloy single flange ball valve, oil discharge port, double door bottom valve, oil measuring hole and other systemsList supporting accessories

Item.Welcome to visit our website【http://www. shhxfcj.com

】The,