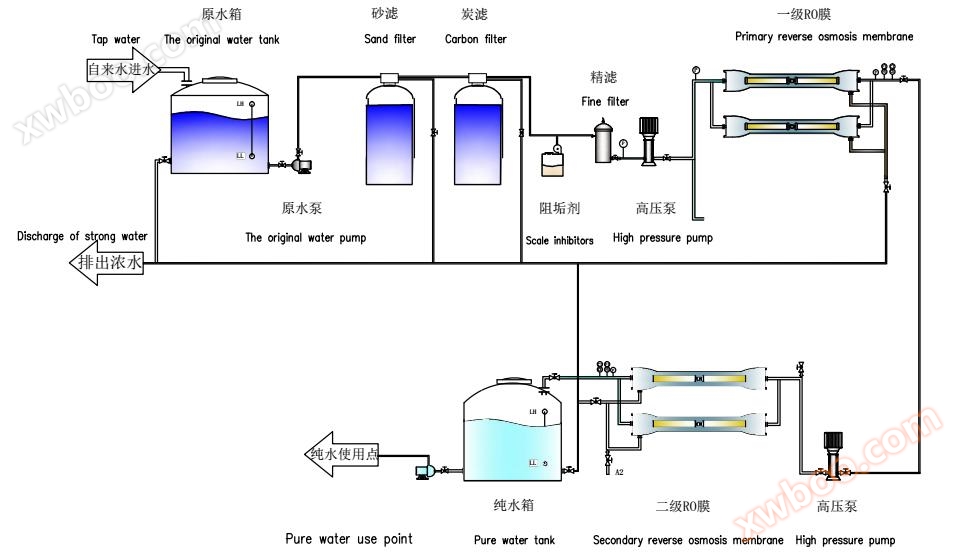

Secondary reverse osmosis purified water systemparameter

Raw water: tap water;

Inlet pressure: 0.2~0.3MPa;

Operating pressure: 0.3~1.5MPa;

Control: Fully automatic control/integrated manual and automatic switching;

Material: Stainless steel 304/316L;

Process: Reverse osmosis membrane separation+Electrodeionization (EDI);

Water production capacity: 0.25~200T/H (depending on customer demand);

产水电阻率: 18MΩ.cm、15MΩ.cm、10MΩ.cm、5MΩ.cm、2MΩ.cm、0.5MΩ.cm;

Standard: Designed in accordance with the pharmacopoeias of China, the United States, and Europe, strictly following GMP standards.

Secondary reverse osmosis purified water systemFunction:

1. Raw water tank, intermediate water storage tank, RO membrane EDI、 Purified water storage tanks can be cleaned online;

2. Horizontal block design and automated control of the entire machine;

3. The preparation system terminal adoptscombine, synthesizeThe dual circulation water supply mode of Geshui enters the purified water storage tank, but notcombine, synthesizeThe grid water circulates back to the intermediate water storage tank. When the purified water storage tank is full, it automatically switches to the self circulating state of each module to ensure that there is no stagnant water in the system;

4. The control system adopts PLC automatic control, in accordance withcombine, synthesizeThe verification requirements of GAMP5 guidelines and the electronic record and signature requirements of 21CFR Part 11;

5. Equipped with online monitoring, timed printing, and water quality exceeding alarm functions to safeguard your production water supply.

Secondary reverse osmosis purified water systemFeatures:

1. The produced water meets the 2000 edition pharmacopoeia purified water standard and can comply with GMP standards.

2. The structural design is simple, reliable, and easy to disassemble. The design of the actuator should use standardized, universal, and systematic components as much as possible.

3. The entire system of the ultra pure water treatment equipment is also composed of all stainless steel materials, which are smooth, flat, without dead corners, easy to clean and sterilize, and corrosion-resistant to prevent rusting.

4. Directly using tap water to produce sterile ultrapure water can completely replace distilled water and double distilled water.

5. Adopt high-quality components such as imported pumps and reverse osmosis membranes.

6. Fully automatic operating system, efficient automatic flushing.

7. Imported instruments are used to accurately and continuously analyze and display water quality.

8. Used for pure water in the pharmaceutical industry, medical infusion preparations, and purification of medical sterile water.

Pasteurization:

Purified water pipelines are generally disinfected using the pasteurization method, and all usage points are closed to check if the water in the storage tank meets the requirements; Heat the purified water in the system to above 80 ℃ using a heat exchanger at the end of the return water, and maintain this temperature for 120 minutes. During the sterilization process, the purified water in the system should be kept in a circulating state.

Advantages of automatic welding for sanitary grade pipelines:

1. No pollution caused by welding fumes;

2. The groove is flat and the pipe end is free of burrs;

3. Uniform welding, no false welding, no dead corners, easy pipeline cleaning, and less likely to breed bacteria;

4. Endoscopic examination can be performed.