Product Introduction

Snow ear packaging machine is a mechanical equipment specifically designed for single packaging of edible fungi such as snow ear, white fungus, and silver ear in the market. The machine can process about 20-200 packages per minute, with high processing efficiency and fast speed.

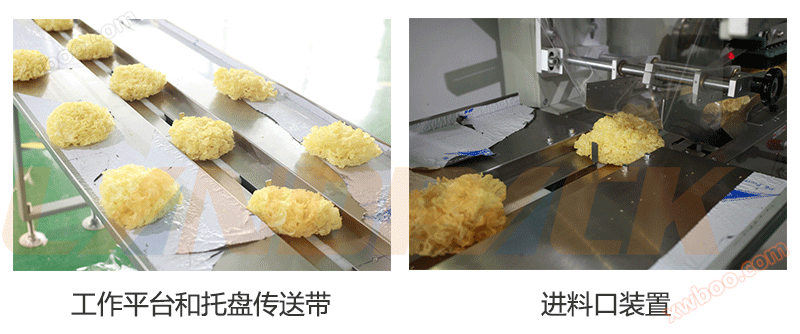

This silver ear packaging machine is a pillow type packaging machine, which is in the form of paper feeding. That is to say, the packaging film is installed on top of the machine. Through the video, it can be seen that the workflow of the device is as follows: the operator manually places the snow fungus, white fungus, silver fungus, and other fungus products that need to be packaged one by one into the tray conveyor belt of the packaging machine, and then the conveyor belt transports the materials one by one to the packaging machine for packaging one by one, and finally outputs the finished product. This packaging machine is used to package individual bags of snow fungus, white fungus, silver fungus, and other fungus foods.

Packaging samples

This packaging machine is suitable for packaging single independent bags of mushroom foods such as snow ear, white fungus, and Tremella fuciformis. The common types of snow ear mushrooms in the market can be packaged using this equipment. If other bag forms are needed, other machine models can be used.

Product parameters

| model | LD-450 |

| Bag length | 150-450mm |

| Bag width | 50-180mm |

| Roll film diameter | Max.320mm |

| Packaging speed | 40-230 packs/minute |

| film thickness | 0.04-0.07mm |

| WIDTH | Max.450mm |

| Product height | Max.75mm |

| Power specifications | 220V 50Hz 2.8KW |

| Machine size | 4030*820*1420mm |

| Bag shape | Back sealed packaging (customizable) |

| Machine price | Face to face discussion (different configurations, prices vary) |

Performance characteristics

1. By using traditional mechanized transmission devices, the work is more reliable and maintenance is more convenient.

2. This machine also has a positioning shutdown function, and the packaging film will not stick to the cutting blade, effectively avoiding waste.

3. The operation of the entire machine is controlled by software, which facilitates the adjustment of various functions and technical upgrades.

4. The heating temperature for both horizontal and vertical seals is controlled by a PID independent system, which is suitable for various packaging materials and films.

5. The induction probe's light eye color code tracks the packaging film and digitizes the input of the sealing and cutting position, improving the accuracy of the sealing and cutting position.

6. The human-machine interface operation sets parameters such as bag length and width, which is convenient and fast. It has a fault display and diagnosis function, and specific problems can be seen on the fault control display screen.

7. The whole machine is controlled by dual frequency converters, and the length and width of the bag can be flexibly set without the need for empty adjustment. It can be set in one step, saving time and consumables.

Detail Display

1. The work platform made of 304 stainless steel ensures that the contact surface between the material and the machine is not contaminated, while also ensuring the corrosion effect of the machine. As shown in the picture, we can place the snow ear that needs to be packaged on the work platform in advance. When the conveyor belt is running, we can directly pick up the materials on the platform for placement, which improves work efficiency. A baffle is installed in the conveyor belt to allow animal materials to enter the feeding port.

2. The packaging machine is equipped with a brush device. When the materials are transported one by one to the end sealing area for sealing, running phenomenon is likely to occur. The main function of the brush is to fix the materials. After end sealing, the entire conveyor belt outputs animal materials, completing the packaging process.

Component Display

1. Simple operation area: Using a large-sized electronic touch screen to control the machine packaging process, it can accurately and conveniently control packaging speed, bag length, bag width, packaging temperature and other parameters.

2. Linkage film rolling shaft: Multiple linkage film rolling shafts are used to coordinate the mold pulling process, which can adapt to more film rolling materials and make the film rolling smoother.

3. Electrical components: The entire machine is controlled by electronic control modules, and all controls are programmed with software to achieve reliable quality and convenient maintenance.

4. Customized metal bag maker: The bag making device folds the film on both sides of the metal panel to tie it into the shape of a bag.

5. Hot pressing sealing area: The machine adopts an independent PID temperature control system, heats the double-sided turntable for sealing, and seals the back of the packaged product to ensure sealing.

6. End sealing cutting area: By rotating the constant temperature heat sealing cutting blade, the bag is sealed at the front and rear ends of the packaged product, effectively avoiding curled edges or loopholes at the sealing position.

7. Transmission mechanism module: A simple transmission system with strong operational reliability and coordination, making maintenance and upkeep more convenient.