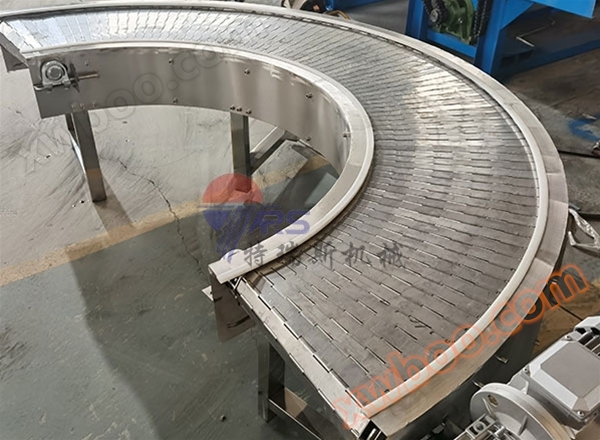

Chain plate turning machines are widely used in the production and application of enterprises. In conveying operations, we often see the role of turning conveyors. The main types of turning conveyors include: turning belt conveyors, turning mesh belt conveyors, turning chain plate conveyors, turning drum conveyors, and so on.

The chain plate turning machine can design the bending angle according to the requirements of each customer. The main bending angles include: 360 degree curve chain plate turning machine, 270 degree curve chain plate turning machine, 180 degree curve chain plate turning machine, 90 degree curve chain plate turning machine, and 45 degree curve chain plate turning machine. These angle turning conveyors are the main turning conveyor equipment produced by Shanghai Yuyin Machinery Co., Ltd., and can also be designed and produced for other non-standard conveyors.

Each customer's product has its own characteristics, so when customizing a turning conveyor, customers should provide us with the following turning conveyor parameter information based on their own product characteristics

1. The conveying angle of the turning machine (such as 360 degree turning machine, 180 degree turning machine, 90 degree turning machine, 45 degree turning machine).

2. Is the power system of a turning machine a non powered turning machine or a motor-driven turning machine.

3. Is the turning machine equipment operated in special environments such as high humidity, high temperature, and the influence of chemicals;

4. What is the bottom of the object that the turning machine needs to transport;

5. What is the approximate weight of the transported items;

6. What are the length, height, and width of the items that the turning machine needs to transport;

The design and installation of the chain plate turning machine should ensure that the transportation route of the parts is relatively short, so as to facilitate close range operation by production workers, assist various service departments in their work, effectively utilize the floor space of production workshops, warehouses, or warehouses, and consider the interconnection between the installation of the turning conveyor. In order to achieve more effective production efficiency, the layout of the turning conveyor must consider the form of the turning conveyor and the arrangement method of the work site when arranging it in a flat layout. In order to achieve better efficiency when the process has two or more workstations and conforms to the entire process operation route. When there are two or more even numbered work sites of the same type, the turning conveyor is required to be arranged in a double row and placed in two separate rows along the transportation route. If a worker is responsible for managing multiple devices while keeping the distance of movement as short as possible, it can achieve better work efficiency within a unit of time.