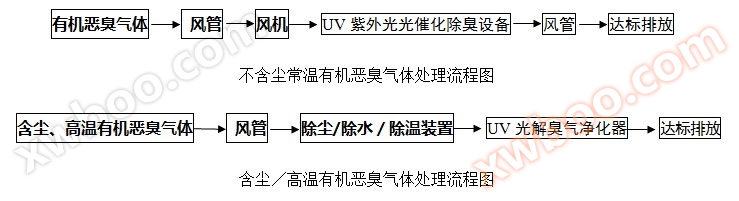

UV ultraviolet lightPhotocatalytic deodorization equipmentWidely used in the treatment of spray painting exhaust gas, ink exhaust gas, plastic exhaust gas, chemical exhaust gas, pharmaceutical exhaust gas, sewage tank odor treatment, feed exhaust gas treatment, casting exhaust gas treatment and other types of exhaust gas with pollution sources and odorous gases for deodorization and purification.

Working principle of UV photocatalytic deodorization equipment:

After the organic waste gas is input into the photocatalytic deodorization equipment through exhaust equipment, high-energy UV ultraviolet beams and ozone are used to synergistically decompose and oxidize the odorous gases, reducing them into low molecular weight compounds, water, and carbon dioxide, which are then discharged outdoors through exhaust ducts.

UVPhotocatalytic deodorization equipmentStructural diagram

UVUV photocatalytic deodorization equipmentProduct Features:

① Low operating costsThis device has low energy consumption (only 0.54 kWh per 1000m3/h processing), no mechanical action, no noise, no need for dedicated management and daily maintenance, only requires regular inspections, and has low air resistance<30pa, which can save a lot of exhaust power energy consumption.

② No preprocessing or environmental requirementsOdorous gases do not require special pretreatment, such as heating, humidification, etc. The equipment can work normally in an environment temperature between -300C-950C, a temperature between 30% -98%, and a pH value between 3-11.

③ The equipment occupies a small area and has a light weightSuitable for special conditions such as compact layout and narrow space, with equipment occupying an area of less than 1.5 square meters and processing an air volume of 10000m3/h.

④ Made of high-quality materialsHigh fire and corrosion resistance, stable performance, long service life, etc.

⑤ Environmentally friendly high-tech productsBy adopting the most advanced international technological concepts and through long-term repeated experiments by experts and our company's engineering and technical personnel, we have developed equipment products that can thoroughly decompose toxic and harmful substances in odorous gases, and achieve perfect deodorization effects. After decomposition, the odorous gases can be completely discharged harmlessly without generating secondary pollution, while achieving efficient and rapid disinfection and sterilization.

⑥ Efficient and fast odor removalIt can efficiently and quickly remove major pollutants such as volatile organic compounds (VOCs), inorganic substances, hydrogen sulfide, ammonia, thiols, as well as various odors. The deodorization efficiency can reach over 90%, and the deodorization effect greatly exceeds the national odor pollutant emission standards (GB14554-93).

⑦ No need to add any substancesOnly the corresponding exhaust ducts and exhaust power need to be set up to allow odorous gases to pass through this equipment for deodorization, decomposition, and purification, without the need to add any substances to participate in chemical reactions.

⑧ Strong adaptabilityIt can adapt to the deodorization and purification treatment of high concentration, atmospheric volume, and different odorous gases. It can work continuously 24 hours a day and operate safely, stably, and reliably.

|

Deodorization treatment technology |

equipment investment |

process air volume |

process concentration |

operation cost |

run management |

Deodorization efficiency |

quadratic pollution |

|

Direct combustion method |

high |

small |

high |

high |

difficult |

high |

have |

|

活性炭吸附法 |

low |

Chinese |

low |

high |

Easy |

low |

none |

|

Chemical catalysis method |

high |

small |

high |

high |

difficult |

high |

have |

|

Ozone deodorization method |

high |

Chinese |

Chinese |

high |

difficult |

Chinese |

none |

|

Biological washing and decomposition method |

Chinese |

Chinese |

Chinese |

low |

difficult |

Chinese |

have |

|

Plasma pyrolysis method |

high |

big |

low |

low |

Easy |

Chinese |

none |

|

UV photolysis method |

low |

big |

high |

low |

Easy |

high |

none |

Comparison between UV Photolysis Waste Gas Treatment Method and Other Treatment Methods

Attachment: National Standard of the People's Republic of China - Emission Standards for Odor Pollution GB14554-93

The standard values for odor pollutants at the factory boundary are the limits for unorganized emission sources (referring to emission sources without exhaust pipes or with exhaust pipe heights below 15m), as shown in the table.

|

serial number |

control project |

unit |

Level 1

|

secondary |

Level 3 |

||

|

New expansion and renovation |

existing |

New expansion and renovation |

existing |

||||

|

1 |

ammonia |

mg/m3 |

1.0 |

1.5 |

2.0 |

4.0 |

5.0 |

|

2 |

trimethylamine |

mg/m3 |

0.05 |

0.08 |

0.15 |

0.45 |

0.80 |

|

3 |

hydrogen sulfide |

mg/m3 |

0.03 |

0.06 |

0.10 |

0.32 |

0.60 |

|

4 |

Methanethiol |

mg/m3 |

0.004 |

0.007 |

0.010 |

0.020 |

0.035 |

|

5 |

Methyl sulfide |

mg/m3 |

0.03 |

0.07 |

0.15 |

0.55 |

1.10 |

|

6 |

Dimethyl disulfide |

mg/m3 |

0.03 |

0.06 |

0.13 |

0.42 |

0.71 |

|

7 |

carbon disulfide |

mg/m3 |

2.0 |

3.0 |

5.0 |

8.0 |

10 |

|

8 |

styrene |

mg/m3 |

3.0 |

5.0 |

7.0 |

14 |

19 |

|

9 |

Odor concentration |

dimensionless |

10 |

20 |

30 |

60 |

70 |

Standard values for odor pollutants at the factory boundary

|

substance name |

The main source of odorous gases |

|

hydrogen sulfide |

Production or processing of kraft pulp, oil refining, coking, petrochemicals, coal gas, manure treatment, carbon disulfide |

|

thiols |

Cowhide pulp, oil refining, coal gas, pharmaceuticals, pesticides, synthetic resin, synthetic fibers, rubber |

|

Sulfides |

Cowhide pulp, oil refining, pesticides, garbage disposal, domestic sewage system |

|

ammonia |

Nitrogen fertilizer, nitric acid, coking, manure treatment, meat processing |

|

amines |

Aquatic processing, livestock processing, leather, bone glue |

|

Indole class |

Fecal treatment, domestic sewage treatment, coking, meat decay, slaughtering livestock |

|

nitro |

fuel |

|

hydrocarbons |

Refining, coking, petrochemicals, calcium carbide, fertilizers, internal combustion engine exhaust, paint, solvents, ink printing |

|

aldehydes |

Refining, petrochemicals, pharmaceuticals, internal combustion engine exhaust, waste disposal, casting |

The main source of odorous gases

UVUV photocatalytic deodorization equipmentScope of adaptation:

Suitable for deodorization and purification of various odorous gases with pollution sources, such as spray painting waste gas treatment, ink waste gas treatment, plastic waste gas treatment, chemical waste gas treatment, pharmaceutical waste gas treatment, sewage tank odor treatment, iron waste gas treatment, casting waste gas treatment, etc. (widely used in the treatment of film sand waste gas, feed fermentation waste gas, spray painting waste gas treatment, enameled wire waste gas treatment, etc.).